Result is usually not an inaccurate flow measurement but rather an unstable flow measurement that can make control difficult or impossible.

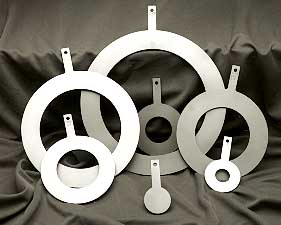

Magnetic flow meter grounding rings.

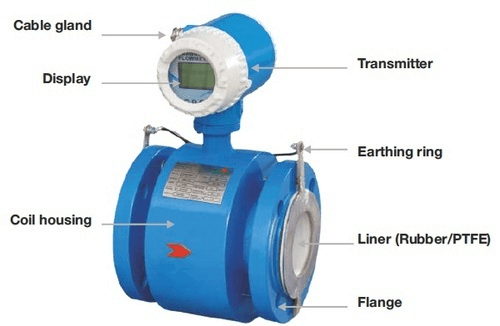

Using two ground rings will provide a path to shunt the current around the fluid in the magmeter.

It is very important to connect both ground rings to the sensor case to minimize the current flow through the process fluid near the electrodes.

This lets the magnetic flowmeter read a stable zero flow and achieve accurate measurement in flow conditions.

Use of grounding rings significantly reduces electrical noise and may be necessary for proper operation of electromagnetic flow meters installed in lined or non.

Current flow through grounding components may occur if.

The grounding ring typically installs on the upstream side of the magnetic flow meter.

Many of the exotic alloy grounding rings are maintained in stock in a variety of materials up to 6.

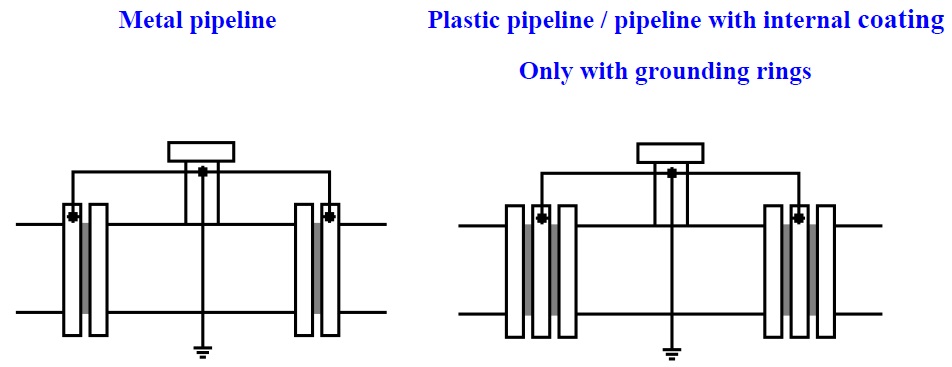

For example grounding rings are very effective when utilized before and after a magnetic flow meter fitting between flanges to ground out unwanted signals in the fluid that can cause inaccuracies in the flow meter s readings.

Use of grounding rings significantly reduces electrical noise and may be necessary for proper operation of electromagnetic flow meters installed in lined or non conductive pipes.

For example grounding rings are very effective when utilized before and after a magnetic flow meter fitting between flanges to ground out unwanted signals in the fluid that can cause inaccuracies in the flow meter s readings.

Grounding rings are flat wafer style rings designed to be installed between the flanges and a mag910 e mag920 or mag930 series inline electromagnetic flow meter flange face.

Ground rings or lining protectors should be connected as shown in figure 5.

Type e grounding rings utilize customer supplied bolts rather then grounding wires or grounding straps.

In some occasions it is not suitable to increase the grounding ring.

In addition to providing the required solution ground placing this grounding ring on the upstream side of the flow tube also provides a fair degree of liner protection to the leading edge of the flow tube s liner when used in moderately abrasive applications.

Other sizes are.

It is important to remember the purpose of the solution ground connection is to serve as a reference point of the flow measurement.

In this situation ground rings provide a path to shunt the current around the fluid in the magmeter.

The size of the grounding rings should always match the meter size as opposed to the original pipe size for installation with inline.

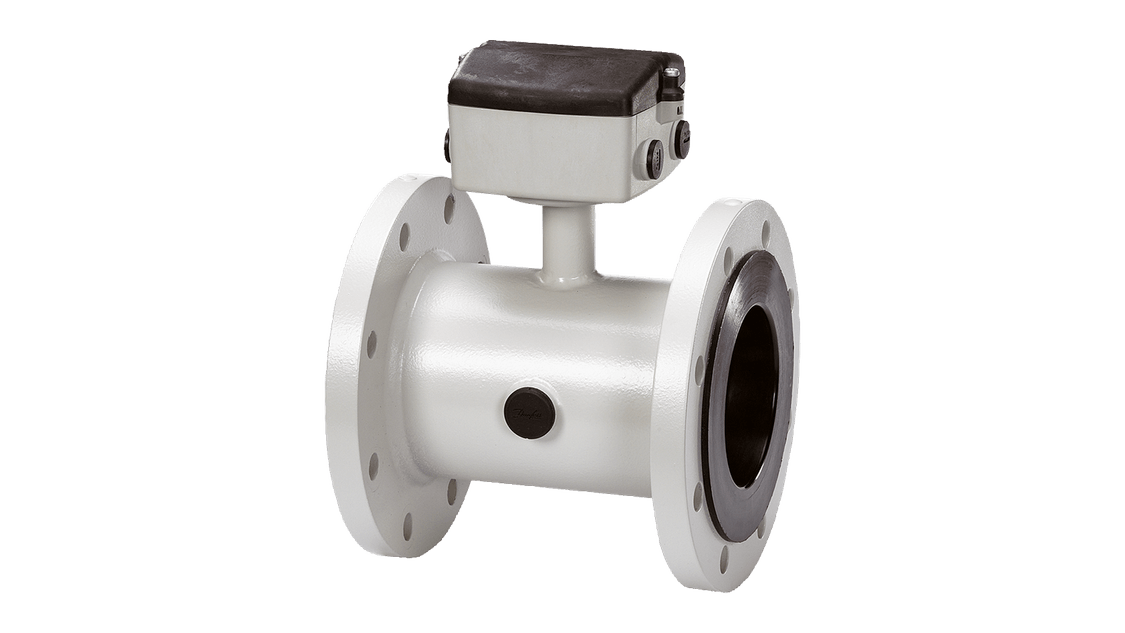

For example when measuring strong corrosive medium the pipe will be made of pvc or ptfe plated electrode which is precious metal especially for large diameter.