A hard but brittle b chemically inert c not permeable to gas and liquid fluid d does not conduct electricity or heat e transparent 4.

Main component of glass and ceramics.

If you can remember those and familiarize yourself with the characteristics of the common ceramic raw materials you are in good shape to start developing your own successful glazes.

In addition ceramics are used in industrial applications including thermal barrier coatings and thermal insulating textiles and electrical insulators for machinery components and sensors.

Glass is a non crystalline often transparent amorphous solid that has widespread practical technological and decorative use in for example window panes tableware and optics glass is most often formed by rapid cooling of the molten form.

Main component of glass is silica.

Properties of glass are.

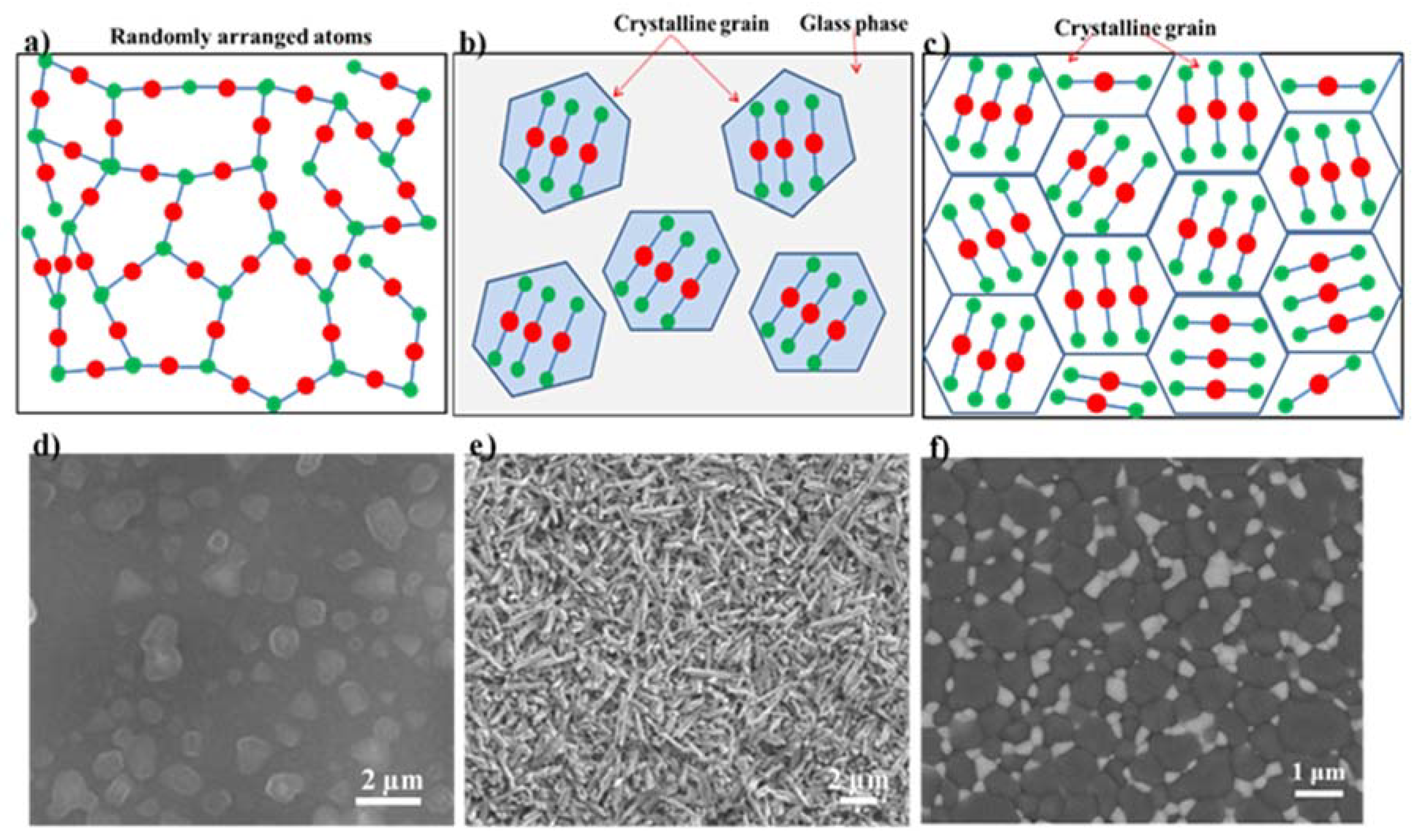

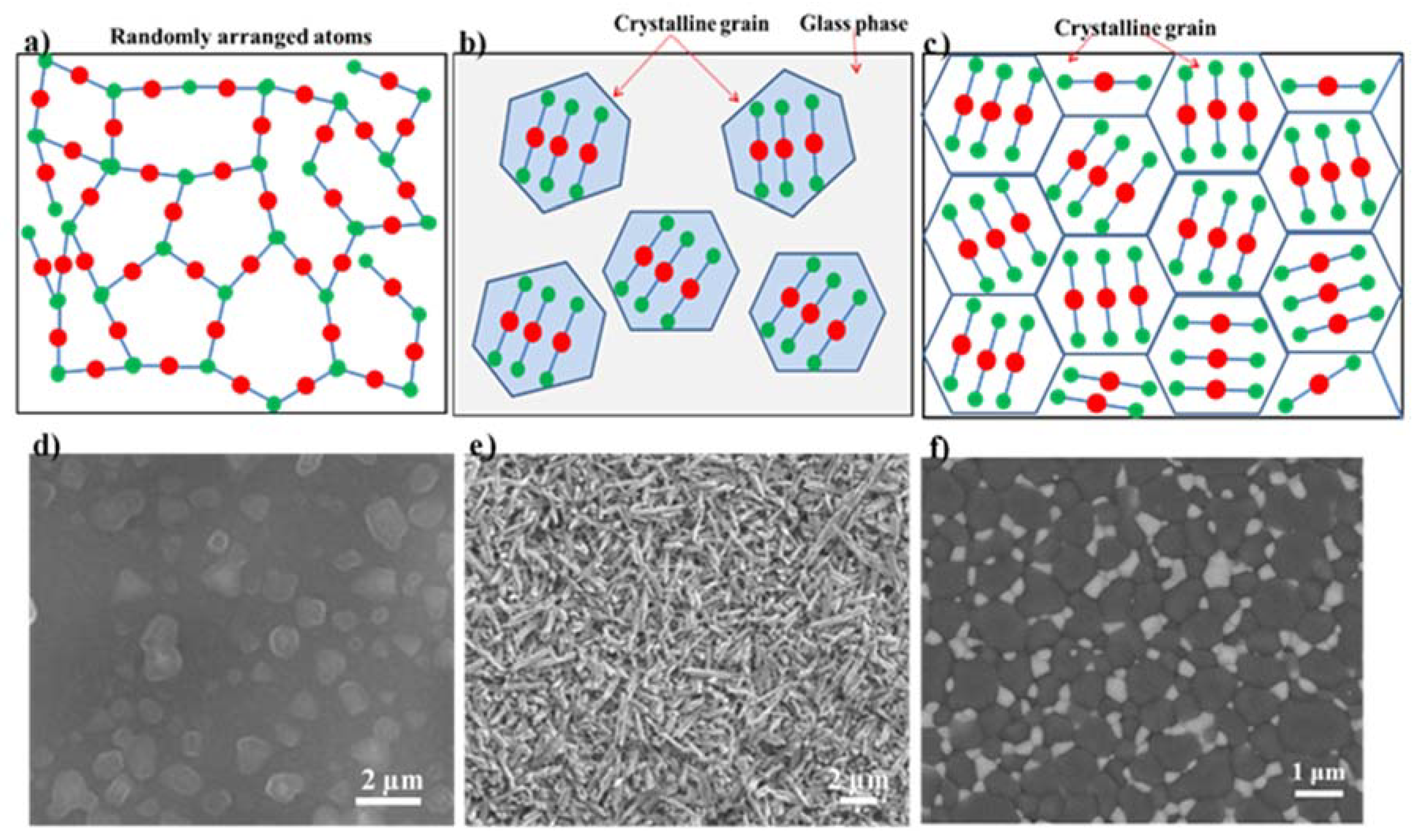

Unlike glass ceramics may have crystalline or partly crystalline structures.

The use of glass depends on their.

However silica s melting point approximately 3100 f or 1710 c is hotter than can be obtained by any ceramic kiln.

When making your own glazes products like quartz flint and pure silica can be added as the glass former.

Usually they are metal oxides that is compounds of metallic elements and oxygen but many ceramics.

Glass is a mixture of of two or more kinds of metallic silicates.

Silicon dioxide is the main component of glass.

Both glass and ceramics are brittle and break at the instance of a small force.

Clay is the main component in ceramics.

In fact if you get it hot enough silica forms glass all by itself.

Ceramics may also be amorphous.

Glass is made from sand.

Ceramic composition and properties atomic and molecular nature of ceramic materials and their resulting characteristics and performance in industrial applications.

Understanding glaze structure isn t hard.

Able to list properties of ceramic able to list uses of ceramic 3.

Some glasses such as volcanic glass are naturally occurring the most familiar and historically the oldest types of manufactured glass are silicate.

Glass formers fluxes and refractories.

The main suppliers of these products are directing their know how in electroceramics toward other components such as ceramic solid state batteries.

From a market standpoint passive components are experiencing the most demand.

Ceramics normally are the compounds between metal and non metal.

Industrial ceramics are commonly understood to be all industrially used materials that are inorganic nonmetallic solids.

Its a good question to point out the difference because glasses traditionally are considered as a type of ceramic.